This assignment was aimed at getting us thinking about the

re-planning and preparation that goes in to any type of field work, and

especially where very high tech expensive equipment is used. As, any time lost

in the field due to lack or preparedness, or failure to assess if the

conditions are suitable, can waste significant amounts of money.

In thinking about the Geographical world today and many of

the data collection that is carried out, some astonishing technological

advances have been made. Data can be collected, quicker, more often, to a

higher standard, with less people, and different data types can be collected.

Much of it involves out sourcing to other professions that have a better

understanding of the data collection. But these professionals can sometimes

have a lack of understanding for the sort o f geospatial thinking that is

required by geographers to carry out fieldwork.

In this assignment we were given 5 scenarios in which

companies may require unmanned air vehicles in order to collect data in aspects

of geographical phenomenon. We had to think about the different things we would

have to survey, how we would do that, the inputs that would be needed from

technology to a sampling method. In order to come up with some ideas that a

company could use in these situations.

Scenario1:

-

A pineapple plantation has about 8000 acres,

and they want you to give them an idea of where they have vegetation that is

not healthy, as well as help them out with when might be a good time to

harvest.

Firstly,

the area is fairly large so if the methods we come up with prove to be too time

consuming or expensive, a sampling

method could always be employed in order to get a general idea of the

vegetation on the land.

Also,

we thought that maybe the type of data that we would be collecting could maybe

be used over several seasons, so may prove to be worth the money and time. We

thought that once it had been highlighted which areas had the pooper quality

vegetation, and which area was best to harvest then, these trends might apply

across a few growing seasons.

I

order to highlight the areas where the vegetation is less health than others,

we felt that a near infrared sensor

could be used. Near infrared sensors detect electromagnetic waves of

wavelength 3.5 to 20 micrometers, as this is the wavelength of moisture particles.

As water is one of the input elements of the process of photosynthesis, we thought that areas where we could detect higher

moisture levels would be areas where the vegetation would be healthier. Figure

1 below shows an example of this type of sensor being put in to practice in

relation to vegetation health. You can see how it clearly shows the different

areas of soil health, and how you could determine which areas were less

healthy.

Figure

1: An example of a near infrared sensor image being used to measure the

health of vegetation in Colorado. (© Federation of American Scientists)

However

it must be taken in to consideration that these sensors can be expensive, and

they must be kept very cold when used, as the radiation that is being sensed is

so weak. In order to acquire knowledge on areas where the plants are ready to

harvest, we thought perhaps a digital camera

could be used in order to see the colours of the landscape and wee where

the crop is ripe enough to pick. This would be a fairly cheaper part of data

collection as cameras are cheaper than remote sensors, but it would have to be

a high resolution camera, in order to detect the image from a significant

height above the fields.

These

sensors would then have to be attached to an unmanned aerial system, in

order to acquire the data from above and keep costs to a minimum. We would

recommend using an Aerosonde, as

theses are commonly used for collecting weather data. It is gasoline powered

which we felt was necessary as we are covering such a large area, and many of

the battery operated ones do not last very long. It has the ability to hold

sensor equipment as many of them come with different sensors, and it can last

about 38 hours in the field in one flight.

We

propose that a flight course would be pre-made to fly the vehicle back and

forth across lengths of the fields taking images along the way until the whole

area had been covered. You may want to carry this fieldwork out just before the

18-20 month growing period is over. Also, seeing as many of the regions where

pineapples are cultivated have cold very hot days but cold nights, it might be

best to fly the unmanned aerial vehicles at night, so as to keep the sensors

clod, but there would still be moisture content in the air. The data on

harvesting times would have to be done during the day, so that the hues of the

vegetation could be seen, and the camera does not require a special

temperature.

Scenario 2:

-

A mining company wants to get a better idea of

the volume they remove each week. They don’t have the money for LiDAR, but want

to engage in 3D analysis (Hint: look up point cloud)

We are presuming that since the company the company wanted

to use LiDar but couldn’t afford it, then the type of mining they are engaged

in is open pit and not underground. We came up with two possible ways for

monitoring the amount removed from the mine each week. One approach would be to

use digital imagery to detect the slag heaps, where measurements could be

carried out from the data collected to detect the volume of matter removed. The

other would be to use a cloud point method

where laser detectors are used to detect and later recreate an area, these

detectors would be flown over the actual mining pit in order to construct the

space, and then once this is done over time we could see how the size changes

and therefore the volume removed could be calculated.

For the first method the data collection should be fairly

quick so that type of unmanned air vehicle we would recommend would be perhaps

a slightly cheaper unmanned aerial vehicle can be used, so as to save money.

The flight time does not need to be that long so maybe even a battery operated

one would be sufficient, a quad copter may

be a good choice as it could fly straight up and over the slag heap and remain

fairly steady and balanced for the image taking.

This data collection would have to be carried out during

the day so that the heap could be seen, and the time of year would only be an

issue if the mine was located in a region that experiences winters with high

precipitation rates, that might obstruct the camera’s view. As the company

wants to know how much it removes each week, the image could be taken once a

week. Then using computer software like ArcMap,

the image could be downloaded a scale applied, and then volume calculations

could be made from measurements made on the computer.

3D scanning can be performed using a regular camera

attached to a UAV and entered into the appropriate modelling software. A steady

camera would be required, such as rotary wing copter with the ability to hover.

A rotary copter is most suitable for hard to reach locations, which may include

some mines. Using this technology an open pit mine can be visualized; from this

visualization it may be possible to determine the volume of the mine. Another

option may be to attach a specific 3D scanning camera to the UAV creating a

point cloud mesh, this option is very similar to LiDar; but would increase the

cost of the survey. Use of 3D sensor camera would yield a more detailed report

of the mine and would be very similar to overhead aerial LiDar and ground LiDar

surveys.

The data collection for the cloud point method will be

quite extensive, as the unmanned aerial vehicle that the sensor will be

attached to will have to cover all of the exposed mine, and may at some points

need to go down in to the pit. So definitely a gasoline powered on would be

appropriate and with a long flight time, so we would recommend a General Atomics GNAT. Also, as the data

needs to be recorded each week, the cost of the vehicle should probably be kept

fairly low.

Scenario 3:

- A military testing range is having

problems engaging in conducting its training exercises due to the presence of

desert tortoises. They currently spend millions of dollars doing ground based

surveys to find their burrows.

The Desert Tortoise is an endangered

species that lives in the Mojave and Sonoran desert of southern California,

Nevada, and Utah. They prefer semi-arid grasslands, desert washes, and sandy

canyon bottoms that are below 3,500ft elevation. They live in burrows that are

3-6ft deep. They are most active in the Spring and least active from November

through February, when they hibernate in burrows. Desert Tortoises depend upon

vegetation such as new cacti growth for food and water; they also consume

calcium-rich soil for digestion, and prefer to burrow in sandy loam soils

(ardisols) with varying amounts of gravel or clay. When rain is anticipated,

the tortoise will dig basins to collect the rainwater. Tortoises also prefer

south facing slopes. A recent study performed by the Department of Defense,

states that tortoises prefer to build burrows under a vegetation canopy near to

a desert wash. (Grandmaison 2010). All of these factors can be used to aid in

locating the tortoise habitats.

Figure 2: An Example of the Unmanned Air Vehicle that we feel would be appropriate to use in the data collection.

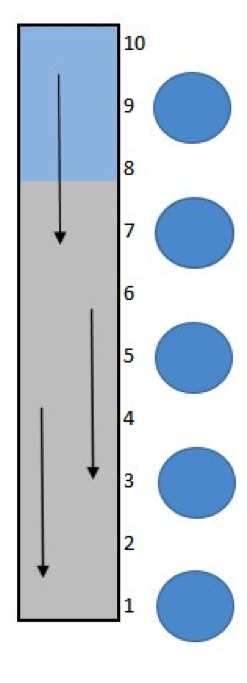

The use

of unmanned aerial systems (UAS) can aid surveyors in determining where Desert

Tortoise burrows are located. There are several options available for UAS,

including a fixed wing UAS, or rotary wing UAS. A fixed wing UAS is more

suitable for covering large areas, and can travel in a preplanned grid flight

path, as shown in figure 2 above. A rotary UAS is more versatile and can be used for small, but hard to

reach areas. A gas powered fixed wing UAS can have up to 10 hours of flight

time, allowing your organization to cover large areas in one survey. A

multi-spectral camera can be attached to this UAS to survey the area and

determine the soil type, vegetation and moisture of the ground below. Since

Desert Tortoises dig their burrows or basins the freshly dug soil may have a

different spectral signature than the ground; a simple remote sensing analysis

of the collected image would be required. The same multi-spectral sensor can be

used to create a false color image that will aid in visualizing areas of high

vegetation and moisture content, which tortoises prefer. The data collected from the fieldwork can be shown in figure 3 below.

Figure 3: An example of the data collection model that would be created during the U.A.V. surveillance.

Other sensors could be used to create a

point cloud which would be used to create a digital elevation model through

photogrammetry. This model would be used to determine elevation and slope.

Combining the vegetation, elevation, slope and soil type information, a habitat

map could be created which highlights key areas that Desert Tortoises prefer

indicating areas also that would be better suited for training exercises. This

survey could be completed in early spring or during the months of November

through February.

Using a simple camera at low altitude

and analyzing the photography would be a low cost option to detecting the

burrows, other options such as using a multispectral camera and perhaps

creating a habitat map would be more expensive.

Scenario 4:

- A

power line company spends lots of money on a helicopter company monitoring and

fixing problems on their line. One of the biggest costs is the helicopter

having to fly up to these things just to see if there is a problem with the

tower. Another issue is the cost of just figuring how to get to the things from

the closest airport.

The first

question for this company would be "How much is 'lots of money?'"

While it was difficult to determine the cost to utilize a helicopter from

websites of companies that provided such services, those used for the purpose

of medical evacuation cost about $6500 per transport in 2010 (Wykes and

Sanford, 2013).

Assuming that a

medical transport would last approximately one- to three-hours, one could

estimate a cost of about $2170-$6500/per hour of specialized helicopter

services. Even so, using the lower end of this estimate, i.e. $2100, a power

company would have to spend about $19500 to use the helicopter services,

assuming a 9 hour workday.

The other major

issue with using a helicopter is that finding a nearby airport may be difficult

in cases where the power lines are located in remote areas. Flying or otherwise

transporting helicopters (e.g. via truck) to such remote areas would only add

to the cost of fuel and per-hour cost of the use of the helicopter.

Another problem

with using full-size helicopters to monitor power lines is that flights would

be weather-dependent. For instance, if the power lines are located in a region

plagued with inclement weather, how likely is it that a cancelled flight would

be able to resume ASAP once the weather improved? Probably not too likely

considering that the helicopter company would probably have other appointments

scheduled with other clients.

The most

effective solution to the problems presented by full-size helicopter inspection

of power lines mentioned above would be to employ an unmanned aerial vehicle to

inspect the power lines for damages. However, a fixed-wing UAS platform (FWP)

would not be recommended in the case of power line inspections due to: 1) the

vehicle's inability to hover and take the pictures/video necessary to asses

damage, if any and 2) the danger that power lines pose to the FWP should it

become entangled in them. The risk of entanglement in power lines also rules

out other, even cheaper, UAS platforms such as kites and balloons for the

inspection of power lines and towers.

The most

practical solution to the problems inherited by inspecting power lines and

towers would be to use rotary wing platforms (RWPs). Following are two examples of RWP systems on

opposite ends of the price spectrum.

The cheapest

resolution that would allow the utility company to effectively monitor its

lines and towers would be to deploy a relatively cheap RC RWP unit to the areas

where the towers are located. For instance, the Align RC 600 Nitro (fig. 4), which

comes as a kit and costs approximately $700, could be retrofitted with a

durable camera on its underside that would allow for the video inspection of

power lines and towers.

The

waterproof Ion-Air Pro 2 helmet camera (fig. 5), for instance, weighs only 4.6

ounces, is small in dimension (1.4 x 1.4 x 4.5 in.), and has 2.5 hours of

battery life. Costing roughly $250 apiece, several of these cameras could be

bought and attached to the Align throughout the workday as the battery fails in

each.

Although the

Align comes as a kit, it would likely be no problem for one of the power

company's maintenance workers to assemble it on site. Replacement parts for the

Align, such as rotary shafts, blades, and fuselages are also available on the

NitroPlanes web page (http://www.nitroplanes.com/15h-kx0160npc.html).

Furthermore,

the relatively cheap cost of the Align RWP would enable more than one copter to

be purchased, thus cutting down substantially on the time it takes to inspect

the towers and lines. For instance, ArcGIS could be used to establish

inspection zones and use a feature class layer to represent the towers. Each

Align operator could carry a GPS unit that was programed with the coordinates

of each tower and geographically "check off" each tower that was

inspected in their respective zone. Towers could also get identifying placards

installed on them so that their unique identifier could be synchronized to

specific coordinates in ArcGIS and the GPS device.

Mobility is

another pleasing aspect to the RWP solution. For example, operators could take

the small (approx. 7.1 pound) Align model with them in their company/all

terrain vehicles (ATVs) to the locations where the inspections would take

place. Once there, the Align could be deployed and the applicable data

collected.

Weather would

not affect Align missions as much as those conducted by companies with

full-sized copters because missions could simply be postponed until weather

permitted their re-initiation. Also, since all the Align operators would be

in-house (i.e. linemen trained to operate the RWP) rescheduling missions would

not be as daunting as compared to doing so for independent helicopter

companies. Furthermore, the low cost of the Align would ensure that if one of

the RWPs did happen to become lost or damaged, a replacement, although not

ideal, would be doable in terms of cost.

One downside

to this particular RWP model (i.e. the Align 600 Nitro) is that its 440 cc fuel tank only allows for

10 minutes of flight time, assuming no payload and ideal conditions. However,

the problem of limited flight time could be solved by simply replenishing the

fuel supply periodically throughout the workday. Also, the Nitromethane fuel

that this RWP uses is relatively cheap costing about $25 per gallon, according

to some internet sources

(http://www.ultimaterc.com/forums/showthread.php?t=176431) and would allow for

84 minutes of continuous flight time, assuming about 3700cc per gallon.

Figure 4: The Align RC

600 Nitro is a nitromethane powered, remotely controlled helicopter. With a

camera attachment, such as the Ion Air 2 in figure 2 below, this device would

be an ideal platform from which to monitor power lines and towers more cost

effectively than current full-sized helicopter services allow

(http://www.nitroplanes.com/15h-kx0160npc.html).

Figure 5: The cheap,

sturdy, waterproof Ion Air 2 helmet camera could be retrofitted to the

underside of the Align RC helicopter (or similar RWP system) in order to

visually inspect power lines and towers for damage. Multiple Ion Airs could be

purchased in order to compensate for the devices 2.5 battery life. (http://www.bestbuy.com/site/ion-air-pro-2-wi-fi-hd-camcorder-blue-black/2174008.p?id=1219070712053&skuId=2174008&ref=06&loc=01&ci_src=14110944&ci_sku=2174008&extensionType={adtype}:{network}&s_kwcid=PTC!pla!{keyword}!{matchtype}!{adwords_producttargetid}!{network}!{ifmobile:M}!{creative}&kpid=2174008&k_clickid=02b4ced1-feed-2e49-2a09-00003036eaf6#tab=overview).

When fitted

with a fuel engine, the Avenger by Leptron (fig. 6) gets about 2 hours of

flight time. The biggest draw-back for the Avenger is its price tag which

equates to about $100,000 apiece (Joyce). The reason for the high cost of the

Avenger compared to the Align 600 is because, in addition to increased flight

time; durability; and performance (i.e. its ability to operate in 40 mph

winds), the avenger is much more versatile in terms of operability. For

instance, the Avenger can be manually controlled by an operator through either

a laptop Windows interface, or via a controller.

Also, a more

sophisticated RWP such as the Avenger can also be flown by using GPS way-points

to guide its flight path (autopilot). This option would be useful as the RWP

could be flown to previously geocoded towers before the operator switches over

to RC mode in order to perform a more precise inspection of the tower. Once

each geocoded tower was inspected, it could be "checked off" the list

if the inspection was a part of routine, preventative maintenance (PM).

Also, the

ability of the Avenger to switch between RC and auto pilot mode is good since

remotely located power lines might be miles from the road. In this case, the

11-pound Avenger could be transported via ATV or company vehicle to the area of

interest and operated by remote control in order to inspect power lines and

towers.

Another

attractive aspect of the Avenger is that Leptron sells specialty cameras that

can be fitted onto the Avenger. These turret-mounted cameras (fig. 7) have

geo-locator capabilities, are stabilized, and can be operated from the

Avenger's remote control as opposed to commercially available cameras that

could be mounted to the avenger in order to cut costs.

One problem

that the power company may have with the Avenger is that its price may limit

the utility company to only one unit, and thus less area covered over a given

time as compared to multiple cheaper units being operated simultaneously, as

given in the Align example.

Figure 6: Image of the

Avenger by Leptron in flight. Although

far more expensive than the Align RWP, the durable Avenger integrates all its

geospatial technology, such as geocoding, geo-locating, and GPS way-points,

into one unit so that data relating to power line and tower inspection can be

easily classified

(http://www.leptron.com/corporate/products/avenger/specs.php).

Figure 7: Some of examples of the more sophisticated, turret-mounted,

remotely operated cameras that can be used fitted onto the Avenger RWP system

(https://www.leptron.com/corporate/products/avenger/camera.php).

While the Align

and Avenger RWP options above both solve the fiscal problems associated with of

utility line inspection via full-sized helicopters, each does so in a different

way. For instance, while the Align option is much cheaper than the Avenger

option, the Align would be much more cumbersome in terms of operation,

mobility, flight time, convenience and data accuracy. That being said, all the

problems associated with the Align option could be solved, but it would require

unconventional synchronization of many different systems such as cameras, GIS,

GPS, and flight operation; whereas with the Avenger option, all these systems

would come already integrated with one another.

However, with

the convenience of the integrated flight, GPS, and GIS systems, as well as

other luxuries such as improved quality and performance in addition to

high-tech camera systems, the Avenger by Leptron comes at a price. While the

price of the Avenger may limit the utility company's ability to purchase more

than one unit, the overall price of the system would still save the company

money in the long run with the unit paying for itself after five or so uses

(assuming $19500/nine-hour day for a conventional helicopter service).

Scenario 5:

- An oil

pipeline running through the Niger River delta is showing some signs of

leaking. This is impacting both agriculture and loss of revenue to the company.

According

to the scenario above, the main problem is that the oil company does not know

where the source of the leak is located on the Niger River Delta (fig. 8).

Following is one method in which the leak could be determined in a cost

effective and efficient manner from an unmanned aerial platform in order to

prevent further damage to the delta environment as well as to the oil company's

revenue.

The proposed

system will not only make locating the leak easy, but will also allow for the

data obtained from the proposed monitoring system to be easily synchronized

with geospatial systems. For instance, taking advantage of such geospatial

programs such as GPS and ArcGIS in order to locate the leaky pipeline.

However, it should

be noted that the following idea involving the use of tethered balloons to

locate the source of the leaking oil on the Niger River are based solely upon

the small amount of information provided by the oil company thus far. It may be

determined that other, more effective unmanned aerial systems may be better

suited to locate the oil leak after the following important questions are

answered by the oil company:

1) How was the leak discovered?

2) What, if any, is the estimated cost of the leak in terms

of its impact on the delta region and in terms of revenue lost to the oil

company

3) What is the estimated area of interest (AOI) of the leak

in both terms of size and geographic location?

4) What measures, if any, have already been undertaken to locate

and stop the leak by the oil company

5) What, if any, has been the involvement of Nigerian

government regarding the matter of the contamination of the Niger River delta

6) Has the oil company consulted with other authorities,

such as environmental consulting firms, on the matter of contamination due to

oil leaking into the Niger River delta?

Figure 8: The general area of interest in the Niger River delta on the west

coast of the African continent. More information from the company whose oil

pipeline is leaking will be needed in order to pinpoint the exact AOI in this

region

The first

problem is that the location of the leaking pipe is unknown. In this case, an

aerial surveillance system consisting of near infrared (NIR) cameras suspended

from tethered balloons will be placed at various, predetermined locations on

banks of the Niger River in order to take aerial photographs of the river's

surface water. NIR cameras attached to each balloon platform would be

periodically retrieved so that the spectral data collected by them could be computationally

analyzed. From this spectral data it could then be determined whether or not a

specific section of the Niger River corresponding to a particular balloon was

contaminated with oil. Once a non-contaminated portion of the river was found,

ground crews could then search between the balloon that exhibited no signs of

an oil leak and the nearest balloon that did downstream of it; this is the area

where the leak should be.

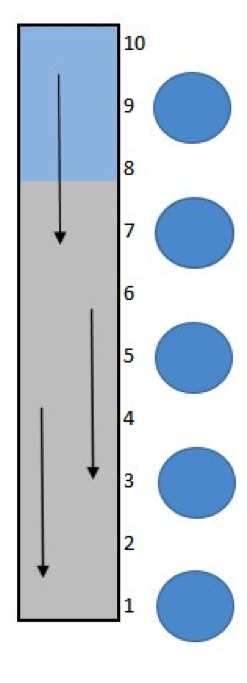

In order to

illustrate this procedure more clearly, figure 2 shows a series of balloons

along the banks of a model river; numbers on the right-hand side of the image

correspond to arbitrarily determined river-miles. Blue and grey shading

corresponds to water that is uncontaminated and contaminated by oil,

respectively, while arrows indicate the direction of water flow. So, for

example, if the sensor on the balloon at river-mile 9 detects no contamination,

but the balloon at river mile 7 does, then it could be reasoned that the leak

in the pipeline is between river-miles 7 and 9 and ground crews could be

dispatched to this area in an attempt to locate the leak.

Figure 9:

illustrates how the source of oil contamination could be determined using a

system of tethered balloons to monitor contamination in the AOI. Balloons in

this diagram correspond to odd-numbered river miles. Each balloon will take a

series of aerial photographs in NIR to locate surficial oil contamination on

the river (grey areas). Once an area the river is found to be free of

contamination (blue) using aerial surveillance, ground crews need only to

search between that balloon and the nearest one exhibiting contamination

downstream of it to find the source of the leak; in this example, between river

miles 7 and 9.

In order to

determine whether or not the water in the Niger River is contaminated, the

correct sensors must be attached to the tethered balloons. Figure 10 shows some

of the spectra associated with oil slicks on water, as determined by the USGS

during the 2010 Deepwater Horizon (DWH) oil spill in the Gulf of Mexico.

While the DWH

spill was likely more massive than the one being examined in this article, the

USGS found that when viewed in infrared

wavelengths, different thicknesses of oil slicks displayed different spectral

signatures. Computational analysis could then be performed on the images

collected by the sensors to determine whether or not the portion of the river corresponding

to that particular sensor was contaminated or not.

Using the

spectral information provided by the USGS, NIR cameras would likely be the best

photographic method for determining whether or not the surface waters on the

Niger River are contaminated with oil or not.

Figure 11

shows an example of a near-infrared camera, from Edmund Optics, that could be

suspended from a balloon platform in order to locate surficial oil

contamination on the Niger River. While far from cheap at nearly $2000 apiece,

this price likely pales in comparison to what the oil company is losing in

revenue and mounting cleanup cost.

Figure 10: An example of the spectra measured by the USGS during the Deepwater Horizon oil

spill in 2010. It was found that when using NIR sensors, thin layers of oil

could be spotted on the surface of the water; i.e. those less than 0.5 mm thick

(blue line).

Figure 11: One of the cheaper NIR cameras offered by Edmund Optics. This device, which

weighs about 90 g and costs about $2000, could be suspended from the tethered

balloon platforms in order to detect thin layers of surficial oil contamination

on the Niger River delta

According

to precipitation graphs for Lagos, Nigeria, which is approximately 200-300

miles away from the AOI on the Atlantic coast, weather should not inhibit the

deployment of balloons except, maybe, in the months of May, June, and July,

when rainfall exceeds 200 mm per month (fig. 5). However, if inclement weather

were to occur on a day when the balloons were scheduled to collect data, their

deployment could be easily rescheduled until a more meteorologically favorable

day.

The cost of

the balloons themselves is very minimal when compared to overall cost of the

spill in terms of ecological damage and revenue lost. Offered by Balloons

Direct, figure 6 shows an example of a weather balloon that could be used in

this project. Each balloon costs about $35 and has a payload capacity of 3

pounds, which is more than enough to lift the 90 gram infrared sensor mentioned

above in figure 4.

In order to

deter theft of the expensive NIR cameras, it would be beneficial to outfit each

camera with a harness system that was easy to detach from its balloon

monitoring platform. This detachable harness system would also be beneficial as

the NIR cameras would need to be removed periodically anyway in order to

download their images onto a computer for spectral analysis.

Balloons could

be tethered to the ground using a rope or cable attached to either a hand

operated or motorized winch. However, the balloons would likely not be very

high off the ground (<20ft.) and a more expensive, motorized winch system

would be more of a luxury than a necessity.

Figure 12: The average precipitation for each month in Lagos, Nigeria, located

approximately 200-300 miles up the Atlantic coast from the Niger River delta.

Based on rainfall averages projected here, the only problematic months for a

balloon launch somewhere in the Niger River delta would be May, June, and July

of any given year; that is, when the precipitation is greater than 200 mm per

each month

(http://www.eldoradocountyweather.com/climate/africa/nigeria/Lagos.html).

FIGURE 13: The cost-effective ($35) "Cloud Buster" weather balloon offered

by balloons direct. Its 3-pound payload capacity would be more than adequate to

lift the 90 g NIR camera shown in figure 4

(http://www.balloonsdirect.com/products/55-foot-cloudbuster-weather-balloon-orange).

While

locating the oil leak on the Niger River Delta is no easy task, regardless of

what method is used to determine its source, the use of tethered balloons

outfitted with NIR-sensors would provide an efficient and cost effective manner

of doing so given the information that was made available by the oil company

thus far.

Once the

questions presented in the beginning of the article are answered, other, more

effective measures may be recommended based on that information. For instance,

if the size of the leak is large enough, the Nigerian government or an

environmental consulting firm may be able to offer further assistance to the

oil company in addition to our services.

Sources:

AAI. 2014. Unmanned Systems. AAI Corporation. Available at: https://www.aaicorp.com/products/unmanned-systems <Accessed on: Friday 14th February 2014>

Clark, R.N., Swayze, G.A., et. al, 2010 , A method for

qualitative mapping of thick oil spills using imaging spectroscopy: http://pubs.usgs.gov/of/2010/1101/ (accessed February

2014).

Dole. Unknown. Pineapple Cultivation. Dole-Plantation. Available at: http://www.dole-plantation.com/Pineapple-Cultivation <Accessed on: Friday 14th February 2014>

El Dorado Weather, 2014, Lagos, nigeria, africa average

annual temperatures:

http://www.eldoradocountyweather.com/climate/africa/nigeria/Lagos.html

(accessed February

Grandmaison, David D., 2010.

Landscape-Level Habitat Associations and. (n.d.). Department of Defense Legacy

Program. Retrieved February 16, 2014, from

http://www.denix.osd.mil/nr/upload/08-385-Technical-Report-Landscape-Level-Habitat-Associations-and-Phylogenetics-of-Desert-Tortoises.pdf

Sanford, J., and Wykes, S, 2013, Study examines

cost-effectiveness of helicopter transport of trauma victims:

http://med.stanford.edu/ism/2013/april/helicopter.html (accessed February

2014).

Unknown. Unknown. UAV: fixed wing or rotary?. (n.d.).

sUAS News. Retrieved February 16, 2014, from http://www.suasnews.com/2013/09/25214/uav-fixed-wing-or-rotary/

Unknown. Unknown. Introduction to Thermal Infrared Remote Sensing.University of California - Santa Barbra, Department of Geography. Available at: http://www.geog.ucsb.edu/~jeff/115a/remote_sensing/thermal/thermalirinfo.html <Accessed On: Friday 14th February 2013>